Fabrice Vandewalle

Sales Manager

fva(at)svanehoj.com

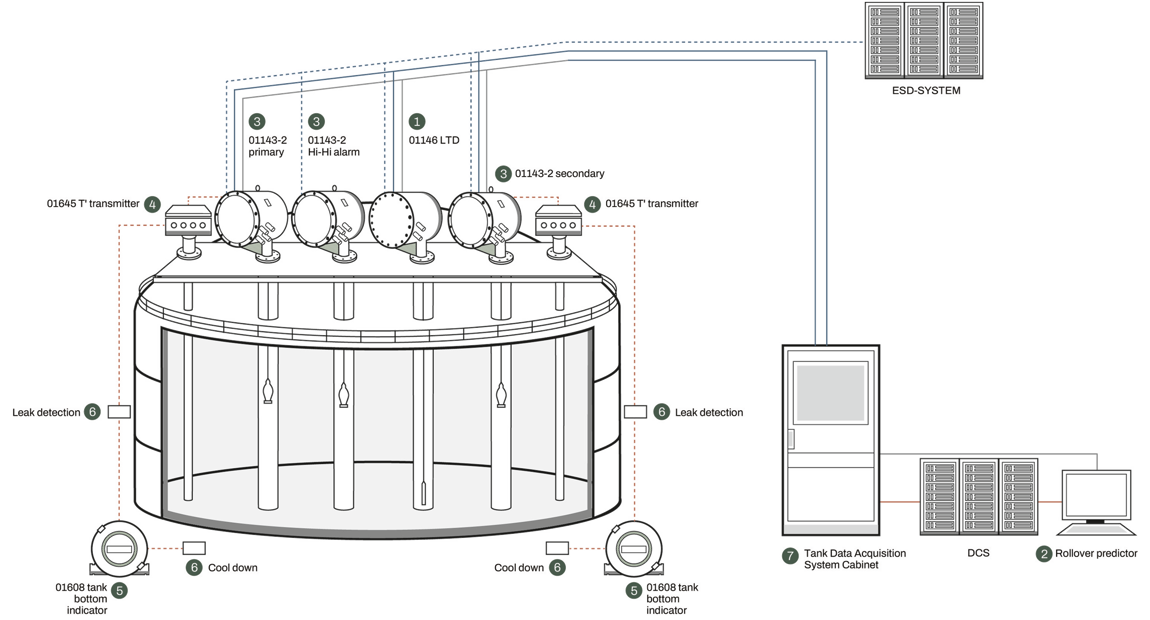

Tank Data Acquisition System Cabinet

The Tank Data Acquisition System Cabinet receives and processes data from field instruments. This data can be linked back to our PLC based redundant acquisition platform or alternatively directly linked to the site’s DCS. In instances where the LNG tank gauging instruments are being linked directly to the site’s DCS system, configuration and maintenance tasks are handled through a portable PC, known as the LNG System Maintenance Supervisor®.

The Tank Data Acquisition System is composed of:

Key features and benefits:

The rollover predictor software is configured for the specific site for which it is intended. It is designed to run in live sites, regardless of the ongoing LNG operations. The software runs while any of the tanks (connected to the same vapour treatment plant) are being filled and/or discharged and takes such dynamic changes into consideration. However, the development of stratification of the tank contents, eventually leading to a rollover, is influenced by many factors far beyond the measurement capabilities of an LTD gauge. Factors that affect the creation, evolution and manageability of LNG stratification and rollover include both fixed (constructional) data and actual, live process data, are considered in the software. Since a rollover predictive calculation is automatically carried out every four hours, fully automatic and independent of manual entries, rollover predictor software will detect a rollover a maximum of 30 days in advance, leaving the operator sufficient time to take corrective actions.

No other company can match our portfolio of products, systems and solutions in these areas.

Whatever your needs, please don’t hesitate to contact us.

Get in touch

Sales Manager

fva(at)svanehoj.com